Challenge: Preventing Injuries Before They Happen

Handheld circular saws are among the most widely used and most dangerous power tools. Traditional safety systems activate only on contact with the blade, meaning that injuries still occur before the tool stops. In high-speed, vibration-heavy environments, conventional optical, ultrasonic, or inductive sensors also struggle with accuracy, limited range, and sensitivity to material properties. The industry urgently needs a contactless safety system that can stop accidents before harm occurs.

What We Did: Ontech CEMF® for Power Tool Safety

Ontech Group developed a Controlled Electromagnetic Field (CEMF®) safety system that projects an invisible protective bubble around the saw blade. Unlike conventional methods, CEMF® continuously monitors distortions in the electromagnetic field, detecting a human hand or body part before it touches the blade.

Our engineering teams designed and validated a CEMF-based proximity detection system specifically for handheld circular saws, overcoming the challenges of metallic structures, vibration, and variable materials. The development process combined electromagnetic field simulations, custom shield circuitry to protect signal integrity, and the design of a multi-frame detection algorithm capable of responding to both fast and slow approach speeds. To ensure consistency and safety, the system was rigorously tested using a purpose-built jig and a virtual testbench.

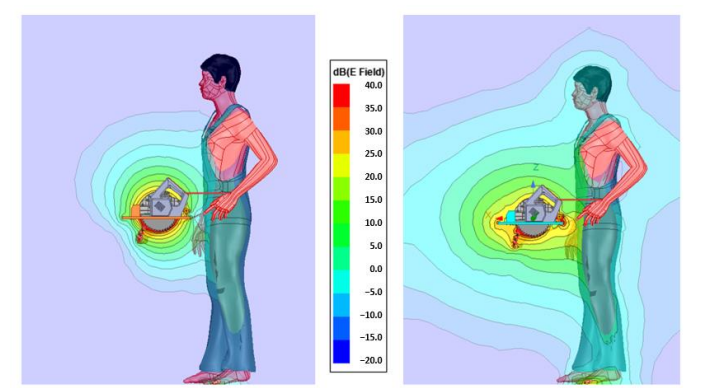

CEMF® Blade Integration

Figure 1. Field simulation of the circular saw with CEMF® integration. The isolated baseplate design projects a wider electromagnetic safety bubble, enabling detection of a user’s hand before contact with the blade.

The breakthrough came from turning the saw blade itself into the sensing electrode. By doing so, CEMF® projects a uniform protective field of up to 25 cm around the blade, creating an invisible “safety bubble.” This early detection provides sufficient time to stop the saw completely before any contact occurs. The approach also adapts seamlessly to blades of different diameters, from 15 cm to 23.5 cm, without compromising sensitivity.

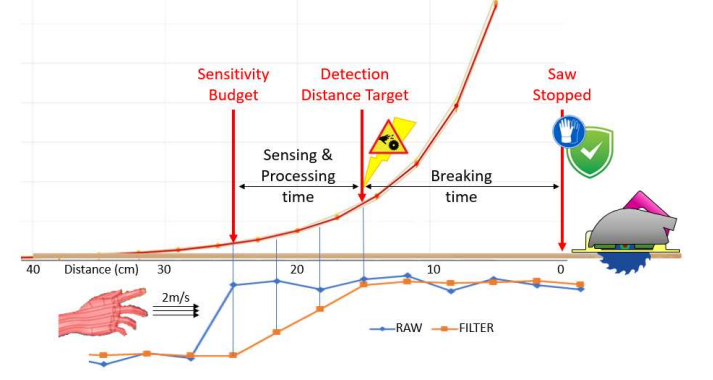

Multi-Frame Detection Algorithm

Figure 2. Sensitivity budget diagram showing how CEMF® detection, filtering, and braking combine to ensure full stop before contact. This underpins the multi-frame algorithm’s ability to handle both rapid and gradual movements.

The second innovation lies in the software layer. A multi-frame detection algorithm continuously monitors at different sampling rates, enabling it to recognize both rapid and gradual hand movements. Advanced compensation techniques filter out noise from vibration and wood cutting, while motor current data is integrated to distinguish between true hazards and normal operation. This combination reduces false alarms while ensuring the system responds instantly when a real risk arises.

Together, these solutions deliver a contactless safety system that transforms circular saw operation, preventing injuries before they happen and ensuring reliable, real-world performance.

Key Advantages Over Traditional Technologies

- Pre-Contact Safety: Detects hands before touching the blade, unlike contact-based systems.

- Material Independence: Works with conductive and non-conductive objects, unaffected by polish or finish.

- Vibration & Metal Resilience: Operates reliably in metallic, high-vibration environments.

- Reduced Tool Stress: Earlier detection lowers emergency stop wear, extending tool life.

- Safety Insights: Logs near-miss events for training and risk prevention.

The Result: Safer Tools, Longer Lifespan

Ontech CEMF® technology redefines safety in handheld circular saws by preventing accidents before they happen. Testing showed that the system consistently stopped the blade prior to user contact, achieving detection distances on average 28% greater than required. By acting earlier, the system reduces the mechanical stress of emergency stops, improving tool reliability and extending service life.

Beyond injury prevention, the technology generates valuable safety insights. Early-warning data highlights near-miss events, allowing companies to identify at-risk behaviours and strengthen training. Together, these results demonstrate how Ontech CEMF® delivers a new standard in operator safety, durability, and workplace accountability.

A Vision for the Future

Ontech Group’s CEMF®-based safety system represents a new benchmark in proactive industrial safety. Beyond circular saws, the same technology can be scaled across power tools, industrial equipment, and even healthcare applications requiring precise human detection. Future research focuses on improving algorithm speed and classification to handle the most complex scenarios without false triggers, reinforcing our commitment to safer, smarter workplaces.

Contact us to explore how Ontech CEMF® technology can make power tools safer and more reliable.